Painting the Eads Bridge with Thomas Industrial Coatings

The job

The first major project TRU’s data collection software was used was the repainting of one of the oldest, most historic bridges in all of the United States – the Eads Bridge in St. Louis, Missouri. This high-profile project was completed in 2016 and funded by the American Recovery and Reinvestment Act of 2009.

The project work completed that related to industrial painting included abating the bridge’s lead coating, prepping its surface to SSPC SP-10 (now AMPP) standards and applying a three-coat application comprised of zinc, epoxy and polysiloxane in order to ensure the structural integrity of the steel-based Eads Bridge.

Why TRU?

According to the painters, project managers, office admins and others at Thomas Industrial Coatings, TRU was the right tool for the job for several key reasons. The biggest of which was that it allowed Thomas Industrial Coatings to be 100% transparent with the other partners on the job – Metro and St. Louis Bridge Construction Company.

“The capabilities for collaboration of people on-site and off-site for anyone involved was very appealing,” said Derek Goff, Thomas Industrial Coatings’ Quality Systems Manager on the job. “From accounting to quality control, [TRU] is helping ensure that everyone is on the same page – sometimes literally and in real-time. With TRU, we’ve noticed improvements in General Contractor and Subcontractor correspondence, and documentation as well has improved safety documentation.”

Additionally, Thomas Industrial Coatings was intrigued by quality assurance that is better ensured through real-time monitoring capabilities by office admins, as well as cost-related documentation that is both improved and expedited.

“The biggest time saver is when we have to reproduce a document,” said Todd Cook, Safety Director at Thomas Industrial Coatings. “Instead of having a foreman working miles away trying to find a fax, I can get the report right off the app and email it quickly to the right party. To me, the best thing about it is the speed.”

Chain of command and workflow

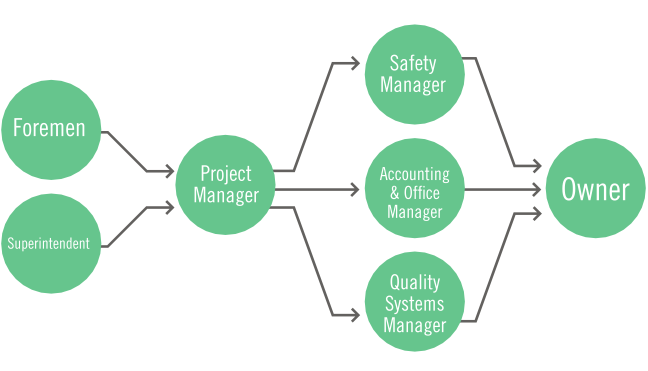

To understand the complexities of the Eads Bridge project, and to really understand the value that TRU is providing Thomas Industrial Coatings, one must first understand the chain of command on the job, as well as day-to-day work flow.

1. The foreman on the job is James Hays and the project superintendent is Matt Thomas. They’re using TRU to help manage time sheets, Toolbox Talks, Take 5s, Daily Inspection Reports and overall quality control measures on the actual job-site. They fill out reports and submit them in for review.

2. The project manager on the job, Tony Wheelock, will review submitted docs, making sure they’re complete and ready for final approval. It’s important to note that sometimes Tony is on the job-site and sometimes he’s in the job trailer. No matter where he is, thanks to TRU, he has access to the reports he needs.

3. Once Tony submits, the general manager on the job, who is in Pevely, Missouri, reviews overall progress and budget for the job. The general manager has final veto power. Once he approves, documents split and go to their respective departments.

4. Thomas Industrial Coatings’ safety manager, Todd Cook, receives the Toolbox Talk, the Take 5, the Weekly Environmental and the Incidental Report.

5. The other documents head toward Betty Wosman, the accounting manager and Dara Nausley, the office manager, who get the expense reports and the foreman’s report. Accounting data is exported to a .csv file and imported into the accounting platform of choice. Thomas uses Sage, so that’s where their reports go. There’s significant time saved in this stage.

6. Finally, the Thomas Industrial Coatings Quality Systems Manager gets the daily inspection report for final approval. This is the same report that St. Louis Bridge Construction Company needs, as they’re the overseer of the job and final approval is theirs to make. With TRU, approval is a simple touch of the screen away.

As you can see, the project chain of command and work flow has lots of opportunities for hiccup and delay. But, with TRU, it’s much easier to keep the job moving, on-time and on-budget.

“Reports actually get signed on a daily basis and are more accurate than they were before.”

— Betty Wosman, Office Manager

Return on investment

Company A reported a 390% return on investment with a paperless job-site documentation and quality control app for the Eads Bridge job.

How savings were calculated

How costs were calculated

The following figures represent TOTAL savings associated with implementing a paperless job-site documentation and quality control app across 25 active jobs for Company A. This paints a more accurate picture of the across-the-board financial effect the app has had on their business.

- Administrative time: $1376/month

(8 hours/week @$40/hr) - Accounting time: $4128/month

(24 hours/week @$40/hr) - Printing and faxing: $1000/month

- Safety director time: $2752/month

(8 hours/week @$80/hr) - Audit preparation time: $1333/month

(40 hours/year x 5 employees @$80/hr) - Field labor: $53,750/month (5 hours/week

x 25 employees @$100/hr) - Office supplies: $100/month (pens, envelopes, binders, paper clips, paper, etc.)

- Equipment savings: $3250/month (computer, camera, GPS savings)

- Approval process time: $6880/month

(admin 16 hours/week @$40/hr; GM/QSM 12 hours/week @$80/hr)

The costs of individual licenses for two foremen and one project manager were calculated across this single job. The individual license costs for one general manager, safety director, one accounting manager and one quality control manager were divided across the 25 jobs with which they’re involved.

- Individual licenses: $149 a user for the 2 foremen and the project manager ($447); the GM, safety, QC and accounting will be divided between all 25 jobs for $24; that totals out at $471

- iPads for seven team members: $70/month (assuming a 24-month hardware lifespan)

- Wireless service on the seven iPads: $68/month

Total costs for Eads Bridge job:

$609/month

Total monthly savings across Company A’s 25 active jobs: $74,569/month

Monthly savings on this Eads Bridge job alone: $2982/month

The intangible benefits of TRU

Safety documentation

In the case of an incident or workman’s comp claim, employee verificiation for non-injury, Toolbox Talk particiaption and daily hazard analysis awareness are documented. All documentation is immediately accessible from both the field and the home office without concern for mismatching data.

Peace of mind

TRU allows you to rest assured knowing all of your documentation is getting done and getting done right.

Avoidance of OSHA/AMPP fines, suspensions and/or loss of QP certification

OSHA audits and requests for pertinent safety documentation can occur anytime, announced or unannounced. AMPP audits occur at minimum once annually and can take the form of a dual audit (office and field).

Fines, suspensions or in worst cases, loss of QP certifications, can be devastating. TRU accounts for the necessary documentation to avoid these situations altogether.

“There are still a few people that do paper expense reports. And those five reports take 30 minutes to do compared to the 70 expense reports I do through TRU that take me only two hours to complete. Guys who used to never turn in expense reports are now. I am getting more thorough information. They tend to put information in right away and are not missing as many receipts since it’s so easy to use.”

— Dara Nausley, Purchasing and Logistics Coordinator